Is Carbon Fiber The Future Of Off Road Vehicles?

In the future there will be fewer vehicles made of steel and more manufactured using carbon fiber. Here is why. Segments of this post originally ran in the March-April 2014 issue of Braintainment Magazine.Carbon fiber is a material on the rise and soon there will be carbon fiber off-road vehicles all over U.S. roads.

In the future there will be fewer vehicles made of steel and more manufactured using carbon fiber. Here is why.

BMW i3 SUV restarts the carbon fiber trend

In July 2013 BMW launched the mass production model of its all electric 4 wheel drive vehicle, the i3. The launch caused quite a spectacle. Celebrities like James Franco and Sienna Miller were flown to the Frankfort Motor Show, to London, to New York and to Beijing. Why was BMW making such a splash about the i3 when all electric cars were not new in 2013? Because the i3 was the first mass production vehicle to have a vehicle body made completely of carbon fiber. But even that is only partially new. Off-road enthusiasts have been modifying the bodies of their Jeeps with Jeep parts made of carbon fiber for years. BMW is leading the pack in an all carbon fiber car body trend that was already rising.

Less weight means higher energy efficiency

The EU has a target of cutting greenhouse gases by twenty percent by 2020 from 1990 levels. The U.S. administration has establish a mandatory increase average fuel economy across fleets to 54.5 miles per gallon by the year 2025. China, the fastest growing automobile market worldwide, imposed strict new fuel economy standards in 2013. Auto manufacturers can not reach the fuel economy standards being imposed in their major markets only by modifying their regular sedans and their economy cars. Design changes will have to be made to trucks and off-road vehicles as well.

That is one big reason carbon fiber is looking so attractive. With auto manufacturers focusing on propulsion, a lighter vehicle body is key. Carbon fiber is about 50% lighter than steel and 30% lighter than aluminum. But this lighter weight does not sacrifice strength. In fact, just the opposite is true. Carbon fiber is five times stronger than steel.

What exactly is carbon fiber?

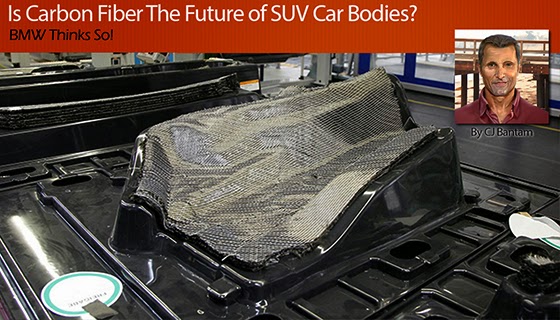

Carbon fiber is made of plastic enforced with tiny fibers made of carbon, making carbon fiber a composite material. It is made the same way one makes paper mache. Strings of very fine carbon fiber are woven together into a mat. The fineness of the strings is 0.00027 inches thick (whereas a human hair is 0.0019 inches thick). The mat is laid on a mold in the shape of the desired car part. Resin or plastic is then poured over the mat. When the mixture is baked the carbon fibers fuse with the plastic. When the mixture cures, the result is an extremely strong material.

Each carbon fiber strand is thinner than a human hair

So strong in fact that it is used in Formula 1 cars, including the monocoque that protects drivers in case of a crash. The material is able to absorb a lot of energy. In BMW's own Euro NCAP tests, the housing of the i3 remained almost intact after a frontal crash at 40 miles per hour. Steel underperforms compared to carbon fiber under the same crash tests conditions. If a passenger has to be cut out of a car after a crash, it is much easier to cut carbon fiber than it is to cut steel. Makes one wonder why more vehicles are not already made out of carbon fiber.

The challenges of recycling carbon fiber

For a long time, the cost of carbon fiber was "expensive". But that was because auto manufacturer's were comparing carbon fiber to the cost of steel. Well, when China went on its economic boom and started building a skyscraper-a-day, the demand for steel, and thus the cost, shot up. In addition, innovation in carbon fiber manufacturing brought the price of the material down.

Now the major challenge with using carbon fiber for auto bodies is recycling it. 25% of the steel used in new cars is made up of steel recycled from old cars. That means car manufacturers pay cheaper "used steel" prices for 25% of the raw material that goes into each new car. Recycled steel is just as strong and durable as new steel. This is not true for carbon fiber. Once the carbon fiber-enforced plastic hardens, it does not become soft and pliable again when reheated. Carbon fiber is not recycled by heating it, it is recycle by grinding it. Once it is ground the properties that made it such a strong material are gone. Ground carbon fiber is used to make mobile devices or patch up holes in the asphalt. But outside of those two uses the applications for ground carbon fiber are rather limited. For now, every time a car manufacturer makes a new carbon fiber bodied car, the manufacturer is paying the "new" price for 100% of all the carbon fiber used.

Industrial scientists are experimenting right now to find ways to grind up carbon fiber chemically, rather than mechanically. The point would be that once the chemical was leached the plastic and the carbon would be separated and available to be used to make carbon fiber all over again. BMW and Boeing partnered a few years ago to form a lab to work on just this challenge. The outlook is hopeful. As more vehicle manufacturers come to use carbon fiber, more recycling centers will specialize in chemically treating it for reuse. With fuel efficiency fleet standards getting stricter and stricter, it is pretty much assured that more carbon fiber bodied cars are coming to the off-road and SUV vehicle space.

Fun Facts About Carbon Fiber

Plastic that is enforced with carbon fiber is new in mass production cars. Plastic with fiber in it being used in auto manufacturing is not new. Here is a slideshow of past vehicles that used materials that preceded carbon fiber as we know it today.

Carbon fiber gains other properties (such as flexibility) from the manner in which the carbon is weaved before the plastic or resin is poured over it. Here are two weave examples.

Biaxial Weave

Plain Weave

Post a Comment